Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PRODUCTS

Product Description

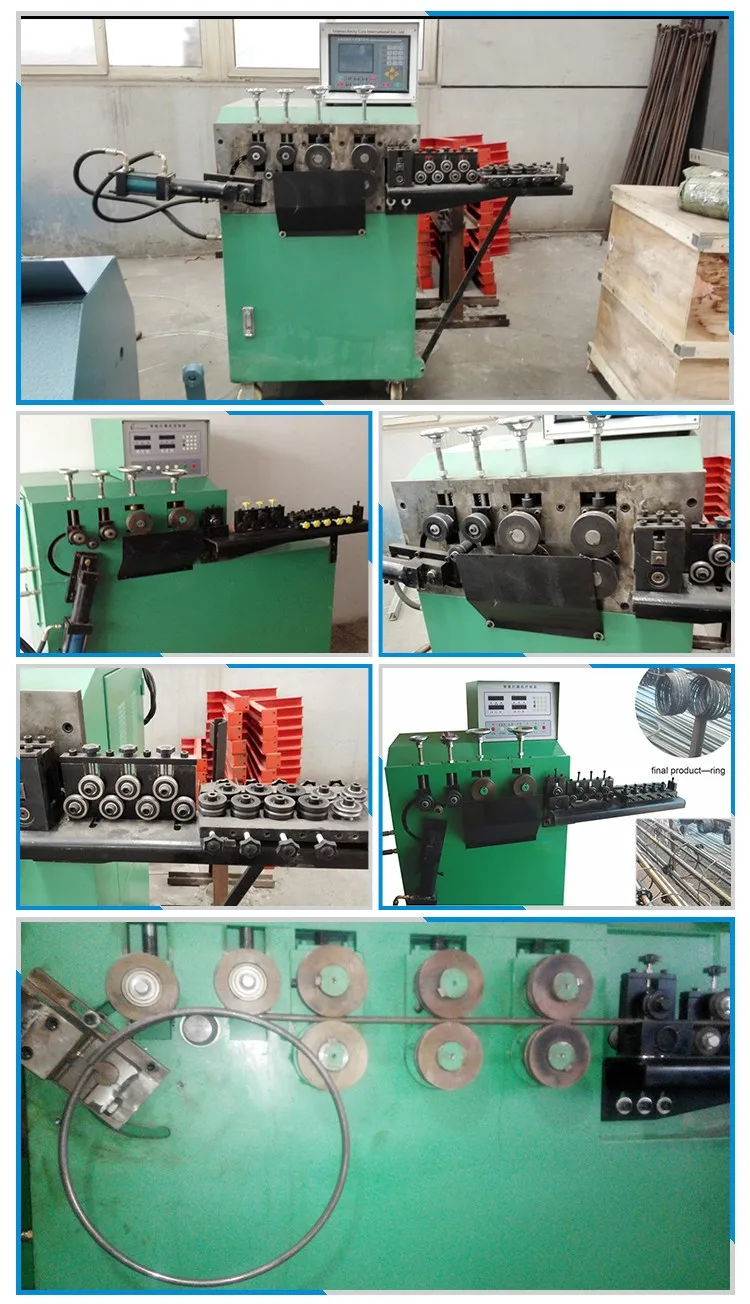

A steel wire ring machine for concrete pile is a specialized piece of equipment used in the construction industry to produce wire circle rings for concrete piles. These rings are used to reinforce the concrete piles, providing added strength and stability.

The machine typically consists of a frame, a concrete pump feeding machine system, a Steel Wire Bending Machinesystem, and a cutting system. The wire feeding system feeds the wire into the machine, while the bending system shapes the wire into a circular shape. The cutting system then cuts the wire to the desired length, producing the wire circle rings.

The machine is usually automated, with controls and settings that can be adjusted to produce wire circle rings of different sizes and specifications. It is designed to be efficient and precise, ensuring consistent and accurate production of the rings.

Some wire circle ring making machines may also include additional features, such as a Rebar Straightening Machine system to straighten the wire before bending, or a welding system to join the ends of the wire circle rings.

Product Description

code | wire Dia (mm) | ring inner Dia (mm) | power (kw) | speed (m/min) | size(mm) |

DQΦ2-Φ6 | 2—6 | 65-850 | 1.5 | 35 | 800*1300*1400 |

DQΦ2-Φ8 | 2—8 | 65-850 | 2.2 | 35 | 900*1300*1600 |

DQΦ3-Φ10 | 2--10 | 100-850 | 3 | 35 | 1000*1300*1800 |

speacial requirements ,we can customize for you | |||||

steel bar ring making machine,bending machine alternate name roll machine, the circle machine, fully automatic digital looped machine, knitting machine is the present domestic most advanced, combines the advantages of Japan, Taiwan and the domestic product, seiko produced beautiful;Advanced control technology, stable performance;Production speed, high accurate product size precision;Have manual slow and reversing function, easy operation, power saving, high yield, low production cost, is popular among customers at home and abroad.

1. Save power, only one set of three-phase motor

2. Smooth and steady: Adopts hydraulic transmission, speed is adjustable,

3. Fast: Transmission is direct, double-gear and double-drive device makes it more powerful

4. Good rigidity,

5. Control system is with the select keys of fast feeding, slow feeding, backward, cutting, auto and manual.

6. With water cycle system, which can cool the machine directly to prevent temperature rise and ensue the looping precision.

YOU MIGHT ALSO LIKE

GET IN TOUCH

If you have any questions our products or services,feel free to reach out to us.Provide unique experiences for everyone involved with a brand. we’ve got preferential price and best-quality products for you.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.